- Type: Cantilever dual spindles

- Main Application: Large plate, Bridge plate, Rib plate, BH plate, and kinds of large or small connecting plate

- Other Application: 1. Drilling for Bridge frame at pre-assembly 2. Drilling for H-Beam Bridge girder

- Control: (IPC+PLC) Industrial PC to process data + Programmable controller to control the positioning and drilling

- Interface: Touch panel + USB slot + CF card

- Home Point: 4 fixed home points + free home point(Searching margin decided)

- Graphic-input: Built-in gallery + coordinate input + teaching-input + DXF file transfer

TACO Series (Dual Cantilever Spindle)

Two spindles are independent-position that can process one big workpiece cooperated or respectively process two different workpieces in the same time.

It is the most reasonable bridge drilling machine with low cost & high efficiency. With crane track, it can process large sheep such as bridge-body plates.

Easy to learn. It is suitable for no matter small-volume and large-variety or mass production.

- Fast-margin with two points

Using the patent tool-center laser-sight device for fast edge searching.

Just aim at home point and any point on the sideline of X/Y-axis to complete edge searching.

The computer will automatically correct the slope of plate.

With BT-40 quick-tool-change Shank the same as machine tools.

Just press the button to load or unload the bit within one second.

The price is only one-third of the traditional Straight Shank’s, but the deflected accuracy of the tool increases 10 times.

- Advanced Hydraulic-Feeding

The independent hydraulic cylinder design makes maintenance more convenient.

With the encoder, it makes the feeding-controlled close to the servo motor and achieve full-automatic feeding stroke management the same as the servo-controlled type.

High-rigidity of machine body and high-efficiency feeding system make feeding achieve up to 0.35 mm per rev. 1.5 mm per rev. when drilling hole 24Ø.

To fast confirm the hole positions.

Check before loading workpieces & adjust supports position to avoid drilling accidentally.

- Hole-Positions Confirmation

Confirm by laser-light cross-center.

- Graphic-Dialogue Input Method

Program producing by graphic-dialogue. Easy to learn.

Input the coordinate directly or use the laser-light cross-center to touch in.

DXF file transfer to a graphic program, even during the drilling operation.

- Multiple Hole pattern Group for Bridge Plate

In response to the property of the bridge connecting plate, it has 10 kinds of holes-group to combine to a program.

Fast restart from unfinished hole when the machine stops for some reason during auto-operation.

Press the button Last/Next Hole to select hole-position to continue processing.

The high-rigid machine and special drill grinder(optional) can achieve high efficiency continuous-drilling operations with automatic chip-cutting, which can reach the same drilling speed as the new Japanese machine.

Ensure the spindle in operating at the other side don’t move to working area when there is loading/unloading.

Programmed auto power-off after the last process cycle.

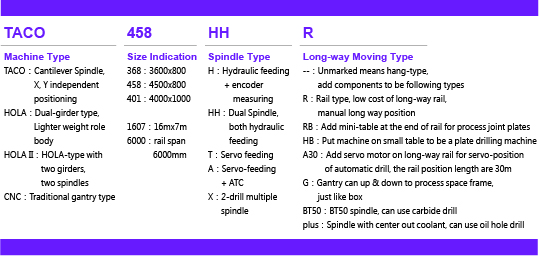

tfi Drilling Machine Type NO.

Detail or other type spec., please contact with us.